A few things:

- When you say "burl" you could mean literally any timber, although eucalypts are most prone to them. Timbers vary considerably with their degree of natural waterproofing.

- While timber boats live for many years in salt water relatively happily, if fresh water collects anywhere, they usually rot in pretty short order.

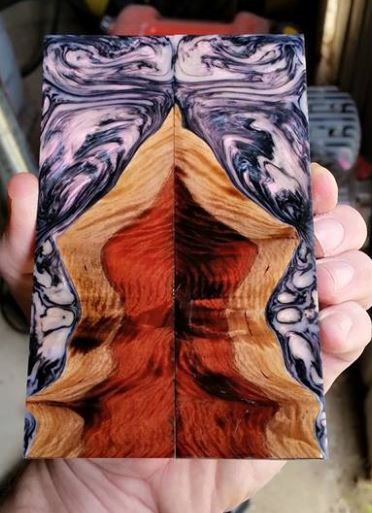

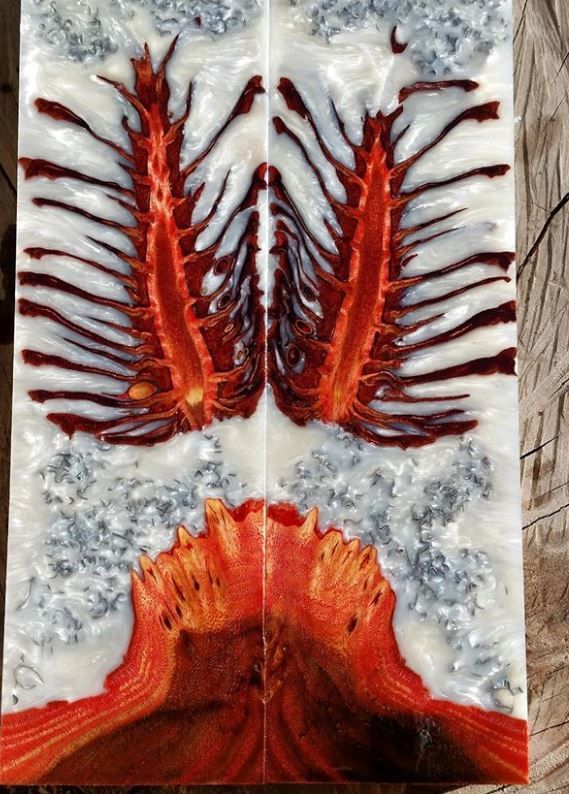

- A burl is likely the result of some bacteria or fungi getting into the timber - this creates weak spaces / air gaps etc that are unpredictable and can get water logged / split a lot easier than the original timber. A trade off for the attractiveness of the variable grain.

- Brushes which get used regularly stay wet a lot longer than a kitchen knife. Normal timber brushes require a good epoxy glue and other waterproofing / sealants to prevent water ingress and bacteria etc growth. Water is the enemy of wood - and transparent sealants of all kinds degrade over time, particularly if regularly exposed to UV. Once degraded, they start letting in water. Unless you keep applying mineral oils of course but not many consumers keep up with that and the joint between knot and handle remains tricky to seal as the wood expands and contracts and the original epoxy ages, again particularly with UV exposure.

- Having said all that, there are some pics of Huon Pine handles on Tony's website. If I was going to source a timber handle, this would be my choice - it's pretty much the most stable and water resistant timber in the world. And it smells fantastic - someone should make a shaving scent out of that smell! The natural oils in the timber would likely seal it longer and better than anything we could add.

Having said all that, plastic handles degrade with UV too - nothing lasts forever! If you like the look, go for your life!