Interesting. It would be helpful to get an idea of why this is in a quantifiable way. ATT, Timeless and Rockwell 6S are all heavy razors, but beyond this I still struggle to see how newer razors are advantageous.

I had a go at trying to find manufacturing tolerance issues on two old razors with stamped steel bases and both were meeting cap to base to within .038mm across the entire edge. If the gap is smaller than this I can't measure it as this is the thinnest feeler gauge I have. All of the capture surfaces were as flat as I'm able to measure with the same limitations. With the stress of bending the blade creating a more rigid edge I suspect this level of tolerance would be largely irrelevant. I also tried to fit a feeler gauge between the blade and the locating lugs in the caps, but whether the feeler gauge was too flexible or the gap is too small is difficult to determine at this scale. Either way the slop is almost imperceptible in both cases.

As quantifiable performance measures go there are really two groups; those which are objective, and those which are subjective. I'm interested to see if there are others I'm not aware of, so here's a list of performance measures by category I can think of, perhaps you folks can think of more?

Subjective (performance benefits which vary by user):

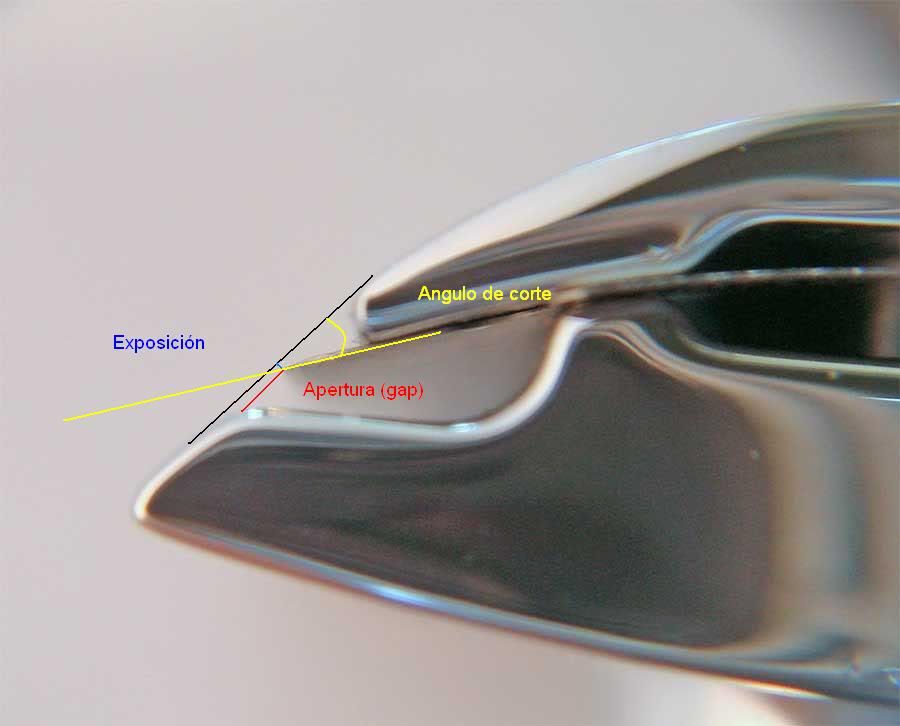

o Blade gap: The clearance between blade and guard measured perpendicular to the shaving surface (straight tangent line contacting guard and cap).

o Sharpness/smoothness: As a function of the blade in use. This is a very big bag of variable in itself.

o Weight: I'm not sure this is really a subjective variable, but I suspect most people will align quality of outcome with weight, making the variable subjective by default.

o Balance: Distribution of weight and balancing point. Again, not sure this should be subjective beyond the human condition.

o Blade presentation angle: The angle of the blade measured against the shaving surface (straight tangent line contacting guard and cap). I suspect this one would be simple to objectify with a statistical trial analysis.

Objective (performance benefits we all agree would be good for everyone):

o Blade straightness: The ability of the razor to maintain a perfectly straight edge to the blade.

o Consistent clearance: The ability to maintain the same blade clearance/gap across the entire cutting edge.

o Tight parallel-ness: The ability to ensure each edge of the blade is presented exactly the same, rather than more aggressive on one side when compared to the other.

o Tight locating tolerance: The ability to locate the blade with minimal slop, such that impact on gap/clearance/parallel-ness is minimised.

That's all I can think of at the moment. Of course, this completely ignores software/prep.

It occurs to me that the phrase "Your Mileage May Vary" is really just shorthand for "There are too many variable to create a complete matrix of tools and conditions to select a tool that will be perfect based on your particular set of conditions". Or TATMVTCaCMoTaCTSaTTWBPBOYPSoC... you know, for short.. :S

I suppose what I mean is this: If you're able to lock down all of the variables, it would be trivial to determine what, if any, advantage is assigned to newer products over older ones. It's clear that some see that newer products do a better job, and I subscribe to this notion, I prefer my Feather to the vintage Gillette, but the scientist in me is screaming to understand why! In my case the sample size is far too small to draw any conclusion. Is it because there is simply more data on the performance of newer products freely available, swaying our purchasing choices, sort of self-reinforcing? Perhaps it's still marketing driven, even though we'd all like to think we're bucking the marketing trend?

I don't know. Perhaps no one else really cares, but it bugs me very badly.